CNC LASER CUTTING

Cincinnati 4,000 Watt Fiber Optic Laser

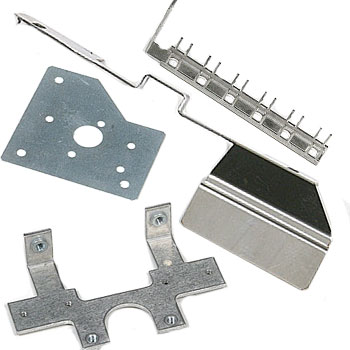

Laser cutting machines offer considerable advantages in productivity, precision, part quality, material utilization and flexibility. We currently operate two lasers, and regularly cut thicknesses up to 3/16″ in aluminum, steel and stainless steel.

The programs for these machines are developed using automated nesting software. This allows for an efficient sheet layout, which results in material cost savings to you. The laser can also be programmed to cut any shape or contour required, which eliminates tooling costs that could be required on CNC punch presses.

The lasers’ high cutting speeds and low machine setup times help us to increase productivity. Lasers can often produce burr free edges, which eliminates the need for additional part processing.

Our 4000 Watt machine also provides additional cost savings. The technology of this fiber optic laser allows us to use ambient shop air to assist in the cutting process. This eliminates the need for costly cryogenic nitrogen or oxygen tanks, which is required for most conventional CO2 lasers.

© GP Precision Sheet Metal • Site by Design-2-Part Web Design.